Top Quality Metal Roof Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE Detail:

Main Character

♦ Completely automatic cutting.

♦ Easy installation, good performance.

♦ Low noise, high efficiency.

Introduction of product operation steps

Hydraulic de-coiler → roll forming → hydraulic punching (2sets) → cutting →curing machine → product

Product introduction

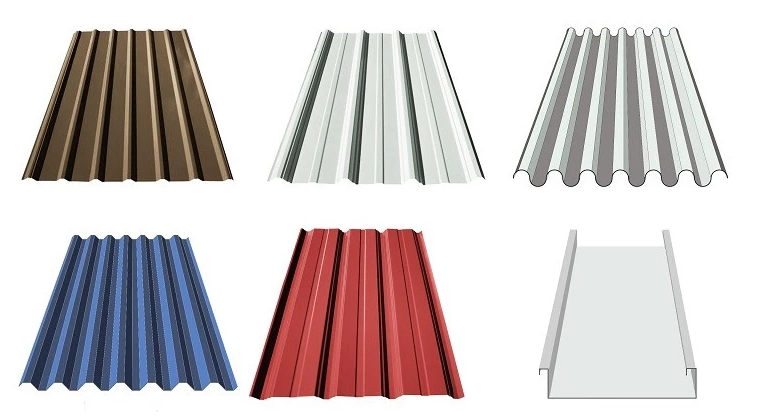

This Corrugated roll forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofs, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Corrugated roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched. It has beautiful, external, classical appearance and elegant taste. We supply the best machine for our customer.

We have dozens of profile model machines for this series of molding, and we can design various profiles and accessories according to customers’ requirements.

Product parameters

| No | Item | Description |

| 1 | Material thickness | 0.3-0.8mm/ 2-4mm |

| 2 | Forming speed | 12-15m/min / 25-30m/min /15m/min |

| 3 | Roll station | 18 stations |

| 4 | Main power | 5.5KW/ 7.5KW/ 37KW |

| 5 | Hydraulic power | 3KW/ 7.5KW |

| 6 | Control system | PLC Panasonic |

| 7 | Drive | By Chain/ by gear box |

Main Technical Specification

| Material thickness: 0.3-0.8mm | Material thickness: 0.3-0.8mm | Material thickness:2-4mm |

| Working speed: 12-15m/min | Working speed: 25-30m/min | Working speed: 15m/min |

| Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) |

| Main power: 5.5KW | Main power: 7.5KW | Main power: 37KW |

| Hydraulic power: 3KW | Hydraulic power: 3KW | Hydraulic power: 7.5KW |

| Control system: PLC Panasonic | Control system: PLC Panasonic | Control system: PLC Panasonic |

| Drive: by chain | Drive: by chain | Drive: by gear box |

Related products

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high-quality handle, reasonable rate, superior services and close co-operation with prospects, we are devoted to furnishing the best price for our customers for Top Quality Metal Roof Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Slovak Republic, Dubai, Malaysia, With the spirit of "high quality is our company's life; good reputation is our root", we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

-

Factory wholesale Concertina Wire Machine - El...

-

Low price for Roll Forming Machine - Metal Dec...

-

Trending Products Deck Floor Roll Forming Machi...

-

Best Price for Steel Slitting Line - Cut to le...

-

Personlized Products Pc Steel Wire Stable Produ...

-

Manufacturing Companies for Highway Guardrail R...