Super Purchasing for Coil Cut To Length Line - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE Detail:

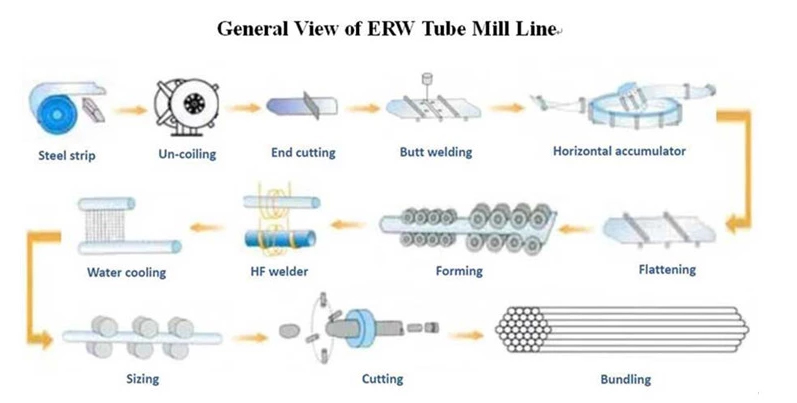

Flow Chart

{Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welder station →→ HORIZONTAL SPIRAL ACCUMULATOR →→Forming M/C (Main driving unit ① +Flattening Entry unit + Breakdown zone + Fin pass zone + Seam guide unit + High-frequency induction welding system + Squeeze welding roller unit + Outside scarfing unit + Zinc spray patching system for welded seam(optional) + Horizontal ironing stand) + Emulsion water Cooling section + Sizing M/C (Main driving unit ② +Sizing zone + Speed testing unit + Turk straightener + Vertical pull-out frame) →→ NC Cold flying saw under computer control→→Run-out table →→{Stacking & packing section (optional)

Product introduction

1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. Specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching.

2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation.

Application

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, military, electric power, mining, coal, machinery manufacturing industries.

Customized Production Line

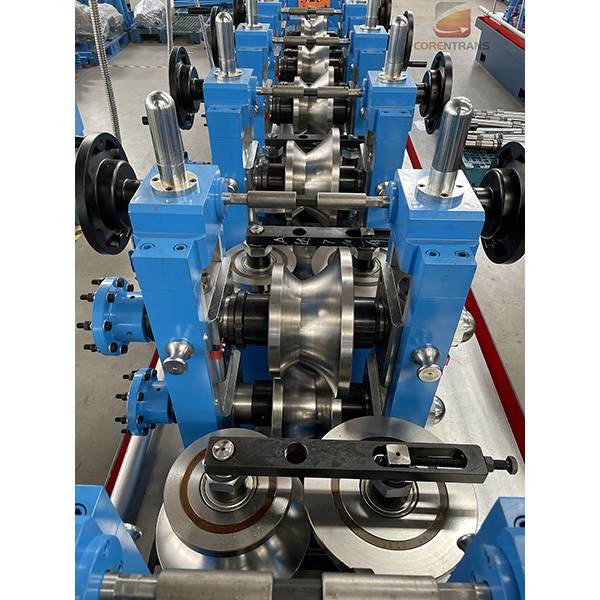

This TM-32 ERW Tube & Pipe Mill, complete with un-coiler & strip-head shearer & butt welder station & forming mill & sizing mill & cold flying saw & conveyor table & stacking & packing machine. The optimized design, high-quality material selection, and strict heat treatment process guarantee the high precision, wear-resisting, and long life of the roller.

ERW Specification

|

Model |

Tube O.D |

Wall Thickness |

Square/Rectangle |

Wall Thickness |

Speed |

Main motor |

H.F.Welder |

|

TM-12 |

φ4~φ12 |

0.2~0.5 |

// |

// |

30~120 |

15 |

100 |

|

TM-16 |

φ6~φ16 |

0.2~0.8 |

// |

// |

30~120 |

22 |

100 |

|

TM-20 |

φ7~φ20 |

0.2~1.0 |

// |

// |

30~120 |

30 |

100 |

|

TM-25 |

φ9~φ25.4 |

0.25~1.2 |

// |

// |

30~120 |

37(or22*2) |

100 |

|

TM-32 |

φ10~φ32 |

0.25~1.5 |

8*8~25.4*25.4 |

0.25~1.2 |

30~120 |

45(or 30*2) |

100 |

|

TM-32z |

0.5~2.0 |

0.5~1.5 |

30~100 |

55(or 37*2) |

100 |

||

|

TM-40 |

φ12.7~φ40 |

0.3~1.8 |

10*10~31.8*31.8 |

0.3~1.5 |

30~110 |

75 |

150 |

|

TM-40z |

0.6~2.0 |

0.6~1.5 |

30~100 |

45*2 |

150 |

||

|

TM-50q |

φ16~φ50.8 |

0.4~1.5 |

12.7*12.7~40*40 |

0.4~1.2 |

30~110 |

90 |

150 |

|

TM-50 |

0.5~2.0 |

0.5~1.5 |

30~90 |

45*2(or 110) |

200 |

||

|

TM-50z |

0.7~2.5 |

0.7~2.0 |

30~80 |

55*2 |

200 |

||

|

TM-63q |

φ19.05~φ63.5 |

0.6~2.0 |

15*15~50*50 |

0.6~1.5 |

30~90 |

132(or 55*2) |

150 |

|

TM-63 |

0.7~3.0 |

0.7~2.5 |

30~80 |

75*2(or 132) |

200 |

||

|

TM-63z |

0.8~3.5 |

0.8~3.0 |

20~70 |

90*2 |

200 |

||

|

TM-76q |

φ25.4~φ76.2 |

0.8~2.5 |

20*20~60*60 |

0.8~2.0 |

30~90 |

160(or 75*2) |

200 |

|

TM-76 |

0.8~3.5 |

0.8~3.0 |

30~80 |

90*2 |

250 |

||

|

TM-76z |

0.8~4.0 |

0.8~3.5 |

20~70 |

300 |

|||

|

TM-90q |

φ30~φ90 |

0.8~3.0 |

25*25~70*70 |

0.8~2.5 |

30~90 |

180(or 90*2) |

250 |

|

TM-90 |

0.8~3.5 |

0.8~3.0 |

30~80 |

110*2 |

250 |

||

|

TM-90z |

1.0~4.0 |

1.0~3.5 |

20~70 |

300 |

|

Model |

Tube O.D |

Wall Thickness |

Square/Rectangle |

Wall Thickness |

Speed |

Main motor |

H.F.Welder |

|

TM-100q |

φ31.8~φ101.6 |

1.0~3.0 |

25*25~80*80 |

1.0~2.5 |

30~90 |

200(or 110*2) |

250 |

|

TM-100 |

1.0~3.75 |

1.0~3.25 |

30~80 |

110*2 |

300 |

||

|

TM-100z |

1.0~4.25 |

1.0~3.5 |

20~70 |

132*2 |

300 |

||

|

TM-114q |

φ35~φ114.3 |

1.0~3.0 |

30*30~90*90 |

1.0~2.5 |

20~80 |

110*2 |

300 |

|

TM-114 |

1.2~4.5 |

1.2~4.0 |

20~70 |

132*2 |

350 |

||

|

TM-114z |

φ40~φ114.3 |

1.2~5.0 |

1.2~4.5 |

15~60 |

350 |

||

|

TM-127q |

φ40~φ127 |

1.2~3.5 |

40*40~100*100 |

1.2~3.0 |

20~70 |

132*2 |

350 |

|

TM-127 |

1.5~5.0 |

1.5~4.5 |

15~60 |

160*2 |

400 |

||

|

TM-127z |

φ50~φ127 |

1.5~5.5 |

1.5~5.0 |

10~45 |

160*2 |

400 |

|

|

TM-140q |

φ50~φ141.3 |

1.2~4.0 |

50*50~110*100 |

1.2~3.5 |

15~60 |

160*2 |

400 |

|

TM-140 |

1.5~5.5 |

1.5~5.0 |

10~50 |

180*2 |

400 |

||

|

TM-140z |

φ60~φ141.3 |

2.0~6.0 |

2.0~5.5 |

10~40 |

180*2 |

500 |

|

|

TM-168q |

φ60~φ168.3 |

1.5~5.0 |

60*60~130*130 |

1.5~4.5 |

10~50 |

180*2 |

400 |

|

TM-168 |

2.0~6.0 |

2.0~5.5 |

10~50 |

200*2 |

500 |

||

|

TM-168z |

φ76.2~φ168.3 |

2.5~8.0 |

2.5~7.0 |

10~40 |

200+132*2 |

600 |

|

|

TM-219q |

φ89.1~φ219.1 |

2.0~6.0 |

70*70~160*160 |

2.0~5.5 |

10~50 |

110*2+110*2 |

500 |

|

TM-219 |

3.0~8.0 |

3.0~7.0 |

10~40 |

132*2+132*2 |

600 |

||

|

TM-219z |

4.0~10.0 |

4.0~9.0 |

10~40 |

132*2+160*2 |

800 |

||

|

TM-273 |

φ114.3~φ273 |

4.0~10.0 |

90*90~200*200 |

4.0~9.0 |

10~40 |

160*2+160*2 |

800 |

|

TM-273z |

4.5~12.0 |

120*60~260*130 |

4.5~11.0 |

10~35 |

180*4 |

800 |

Application Display

Application:

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries.

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Super Purchasing for Coil Cut To Length Line - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE, The product will supply to all over the world, such as: New Zealand, San Francisco, Honduras, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Excellent quality Corrugated Steel Panel Roll F...

-

Wholesale Dealers of Coil Slitting Line - High...

-

High Quality C Purlin Forming Machine - Expand...

-

100% Original Roofing Roll Forming Machine - M...

-

Massive Selection for Automatic Roll Forming Ma...

-

High reputation Steel Tube Mill For Sale - Cut...