One of Hottest for Corrugated Sheet Rolling Machine - Corrugated Roll Forming Machine – COREWIRE Detail:

Main Character

♦ Completely automatic cutting.

♦ Easy installation, good performance.

♦ Low noise, high efficiency.

Introduction of product operation steps

Hydraulic de-coiler → roll forming → hydraulic punching (2sets) → cutting →curing machine → product

Product introduction

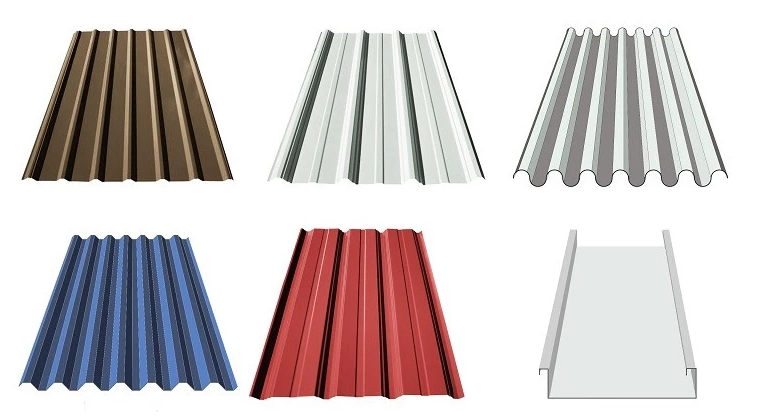

This Corrugated roll forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofs, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Corrugated roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched. It has beautiful, external, classical appearance and elegant taste. We supply the best machine for our customer.

We have dozens of profile model machines for this series of molding, and we can design various profiles and accessories according to customers’ requirements.

Product parameters

| No | Item | Description |

| 1 | Material thickness | 0.3-0.8mm/ 2-4mm |

| 2 | Forming speed | 12-15m/min / 25-30m/min /15m/min |

| 3 | Roll station | 18 stations |

| 4 | Main power | 5.5KW/ 7.5KW/ 37KW |

| 5 | Hydraulic power | 3KW/ 7.5KW |

| 6 | Control system | PLC Panasonic |

| 7 | Drive | By Chain/ by gear box |

Main Technical Specification

| Material thickness: 0.3-0.8mm | Material thickness: 0.3-0.8mm | Material thickness:2-4mm |

| Working speed: 12-15m/min | Working speed: 25-30m/min | Working speed: 15m/min |

| Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) |

| Main power: 5.5KW | Main power: 7.5KW | Main power: 37KW |

| Hydraulic power: 3KW | Hydraulic power: 3KW | Hydraulic power: 7.5KW |

| Control system: PLC Panasonic | Control system: PLC Panasonic | Control system: PLC Panasonic |

| Drive: by chain | Drive: by chain | Drive: by gear box |

Related products

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for One of Hottest for Corrugated Sheet Rolling Machine - Corrugated Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Turkey, Bahrain, Nepal, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Wholesale Price Tube Mill Machine Price - Cut...

-

Discountable price Saw Blade Grinding Machine -...

-

Wholesale Corrugated Roof Panel Roll Forming Ma...

-

China Supplier Cut To Length Lines - stainless...

-

China New Product Ctl Shear - Automatic High S...

-

Manufacturer of Nail Making Automatic Machine -...