The wire drawing machine utilize the metal plastic characteristics of steel wire, pull the steel wire through the capstan or cone pulley with the motor drive and transmission system, with the help of the drawing lubricant and drawing dies generating plastic deformation to get the required diameter and strength.

According to different way of lubrication and working mode, the wire drawing machine is divided to below types:

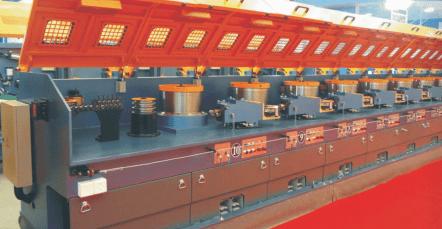

1. Straight Wire Drawing Machine

The feature of the straight wire drawing machine is the steel wire wrapped around the block to a certain height and then enters to the next drawing die, wrapped on the next block. There is no pulley, guide roller or tension roller in between, the steel wire runs in a straight line between the blocks, which reduces the wire bending in the process of wire drawing. Besides, there will be back tension during drawing which is able to reduce the drawing force, reduce the wear of drawing die and prolong usage life of the die, reduce power consumption and other advantages.

2. Dancer Arm Wire Drawing Machine

The dancer arm wire drawing machine is designed on the basis of the straight wire drawing machine, enlarge the distance between the dancer arm and wire inlet guide roller, prolong the reaction time and improve the reaction accuracy.

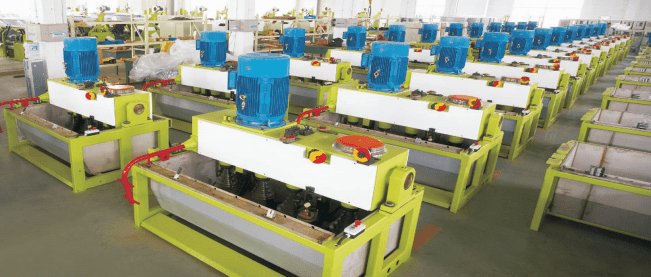

3. Inverted Vertical Wire Drawing Machine

Inverted type wire drawing machine is designed for heavy weight continuous non twisting operation, drawing machine with double functions of drawing and winding. The utility model is suitable for drawing high, medium and low carbon steel wires, special-shaped steel wires, stainless steel wires and coarse non-ferrous metal wire rods, and is especially suitable for the standard parts industry and the shelf manufacturing industry. The maximum diameter of the incoming line can reach 30mm, the diameter of the drum is 600 to 1400mm, and the diameter of the drawn wire is φ 6.5- 12mm.

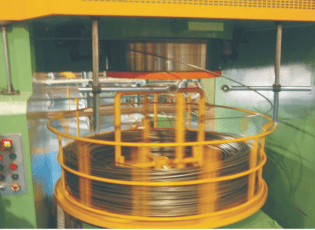

4. Wet Drawing Machine (fits for steel cord wires; cutting steel wires; high, medium & low carbon steel wires)

Wet drawing machine is small continuous production equipment consists of multi drawing steps, the drawing heads are all emerged in the cooling lubricating liquid in the water tank, draw the wire to the required size.

It’s applicable to drawing spring steel wires, bead wire, steel wires for ropes, optical fiber steel wires, CO, shield welding wires, flux cored electrodes for arc welding, alloy and stainless steel wires, aluminum clad wires, PC wire wires and so on.

Post time: Apr-27-2021