Manufactur standard High Speed Nail Making Machine - Cold Rolled Ribbing Machine – COREWIRE Detail:

Product introduction:

|

Product |

Pictures |

Quantity (Set) |

Remark |

| Flying shear cutting machine |

1 |

17KWCNC servo flying shear motor, synchronous motor | |

| Hydraulic Spooler Take-up |

1 |

||

| Control Cabinet |

1 |

Digital control | |

| Straightening Machine |

1 |

Multi-wheel straightening machine to straighten finished products.Multi-wheel small diameter and high frequency straightening method to straighten the finished product.Number of straightening wheels: 24 | |

| Rack |

1 |

||

| Pneumatic Packing Machine |

1 |

Packing Strip width: 14/16mmStrip thickness: 0.38-0.8mmWeight: 5KGPneumatic pressure: 0.42-0.6Mpa

Tension speed: 0.5m/min |

|

| Butt Welding machine |

1 |

Motor power: 10KWFunction: Connecting steel bars together |

Product advantages:

1. Cold Rolled Ribbing Machine is the most developed machine with compact structure, small footprint.

2. Cold Rolled Ribbing Machine is featured by small size, short-distance recycling winding and high capacity.

3. Gearbox Reducer of cold rolling ribbed steel bar is large torque, low noise, durable.

4. Advanced frequency inverter technology can save 40-60% power.

5. Pure steel mill foundry and no cracking.

Product Applications:

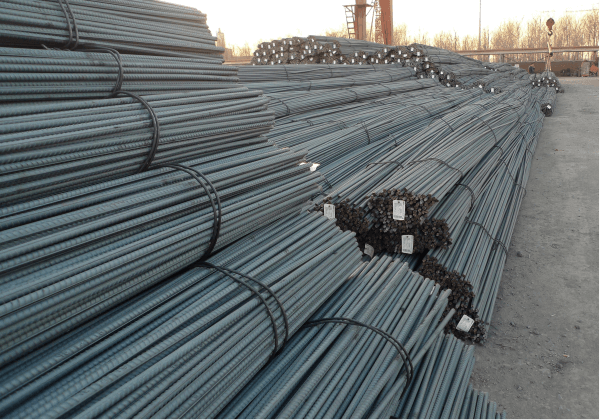

Cold rolled ribbed steel bars have been widely used in construction projects, highways, airports, municipalities, water and electricity pipelines. The high strength of steel can save construction steel and reduce the cost of construction.

Product Parameters

| Item | 20000T | 30000T | 50000T |

| Maximum steel bar process diameter | φ6 -13.5 mm | φ6.5 -12 mm | φ6 -16 mm |

| Diameter of finished steel bar | φ5 -12 mm | φ5.5 -11 mm | Φ6 -14mm |

| Straightening speed | 120 m/min | 180 m/min | 190 m/min |

| Shearing mode | Frequency conversion flying shear | Servo flying shear | Servo flying shear |

| Main motor power | 55-75 KW | 110 KW | 130-160 KW |

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Manufactur standard High Speed Nail Making Machine - Cold Rolled Ribbing Machine – COREWIRE, The product will supply to all over the world, such as: Moldova, Benin, Japan, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

Low price for Roll Forming Machine - Metal Dec...

-

Bottom price High Frequency Welding Tube Mill -...

-

OEM Supply Construction Steel Tiles - C/Z Purl...

-

China wholesale Straight Line Wire Drawing Mach...

-

Best quality Tube Mill For Sale - Cut to lengt...

-

Factory source Iron Nail Making - Electrode Ro...