High Performance Door Shutter Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE Detail:

Main Character

♦ Completely automatic cutting.

♦ Easy installation, good performance.

♦ Low noise, high efficiency.

Introduction of product operation steps

Hydraulic de-coiler → roll forming → hydraulic punching (2sets) → cutting →curing machine → product

Product introduction

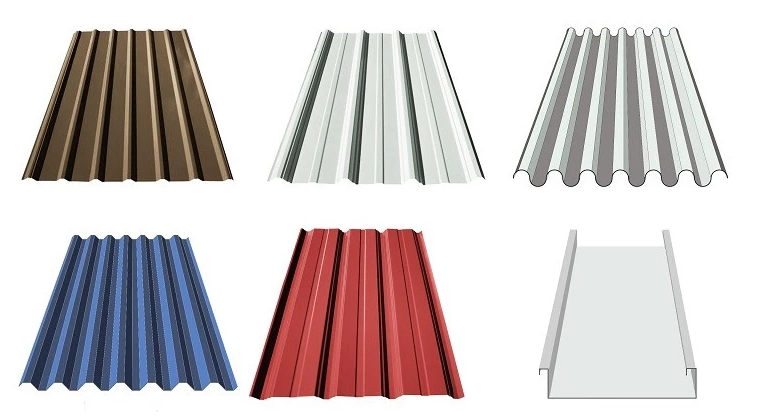

This Corrugated roll forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofs, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Corrugated roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched. It has beautiful, external, classical appearance and elegant taste. We supply the best machine for our customer.

We have dozens of profile model machines for this series of molding, and we can design various profiles and accessories according to customers’ requirements.

Product parameters

| No | Item | Description |

| 1 | Material thickness | 0.3-0.8mm/ 2-4mm |

| 2 | Forming speed | 12-15m/min / 25-30m/min /15m/min |

| 3 | Roll station | 18 stations |

| 4 | Main power | 5.5KW/ 7.5KW/ 37KW |

| 5 | Hydraulic power | 3KW/ 7.5KW |

| 6 | Control system | PLC Panasonic |

| 7 | Drive | By Chain/ by gear box |

Main Technical Specification

| Material thickness: 0.3-0.8mm | Material thickness: 0.3-0.8mm | Material thickness:2-4mm |

| Working speed: 12-15m/min | Working speed: 25-30m/min | Working speed: 15m/min |

| Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) |

| Main power: 5.5KW | Main power: 7.5KW | Main power: 37KW |

| Hydraulic power: 3KW | Hydraulic power: 3KW | Hydraulic power: 7.5KW |

| Control system: PLC Panasonic | Control system: PLC Panasonic | Control system: PLC Panasonic |

| Drive: by chain | Drive: by chain | Drive: by gear box |

Related products

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for High Performance Door Shutter Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Kuala Lumpur, Hyderabad, Puerto Rico, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

-

Free sample for Standing Seam Roof Roll Forming...

-

Super Purchasing for Coil Cut To Length Line -...

-

High reputation Roofing Wall Panel Roll Forming...

-

Factory Free sample Guardrail Roll Forming Mach...

-

OEM Supply Construction Steel Tiles - Corrugat...

-

Newly Arrival Wet Wire Drawing Machine - Elect...