-

Factory Price Decoiling Slitting Line - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE

Flow Chart {Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welde... -

Factory wholesale Decoiling Machine Cut To Length - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE

Flow Chart {Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welde... -

OEM/ODM Manufacturer Hr Tube Mill - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE

Flow Chart {Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welde... -

Massive Selection for Tube Rolling Mill - stainless-steel Industrial pipe making machine – COREWIRE

Applications: Mainly used for the production of stainless steel/carbon steel pipes/tubes with he... -

Hot New Products Tube Mill - Cut to length line – COREWIRE

Introduction of product operation steps This line is composed of coil car, double support un... -

New Arrival China Electrode Rods E6013 - High Speed Nail Making Machine – COREWIRE

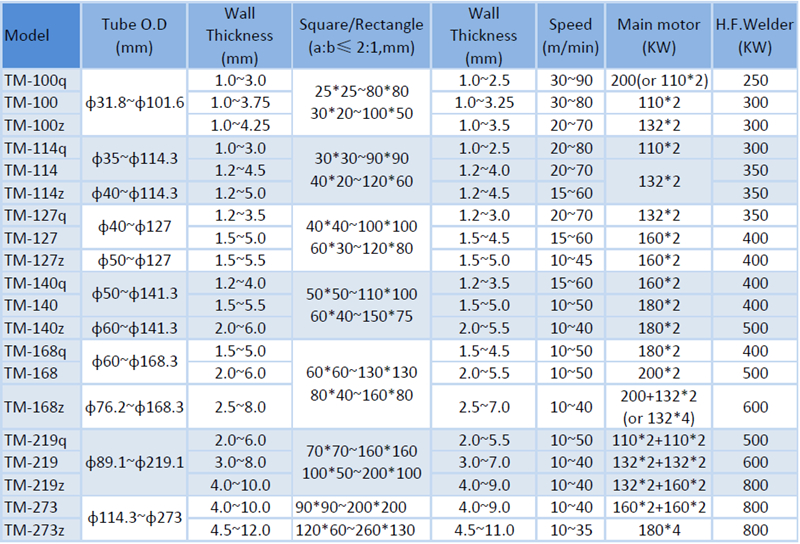

High Frequency ERW Tube & Pipe Mill Machine

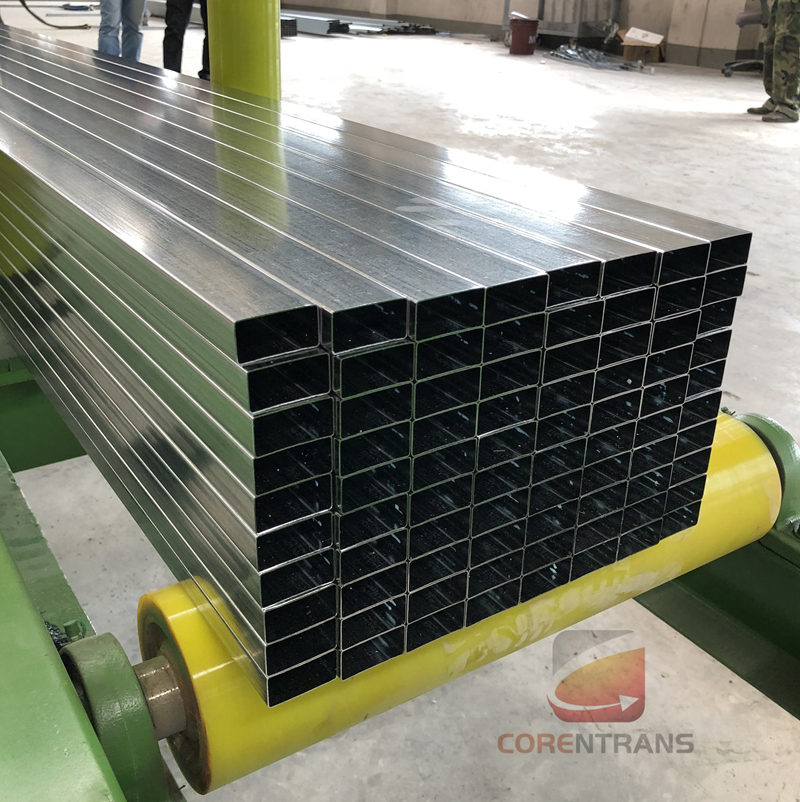

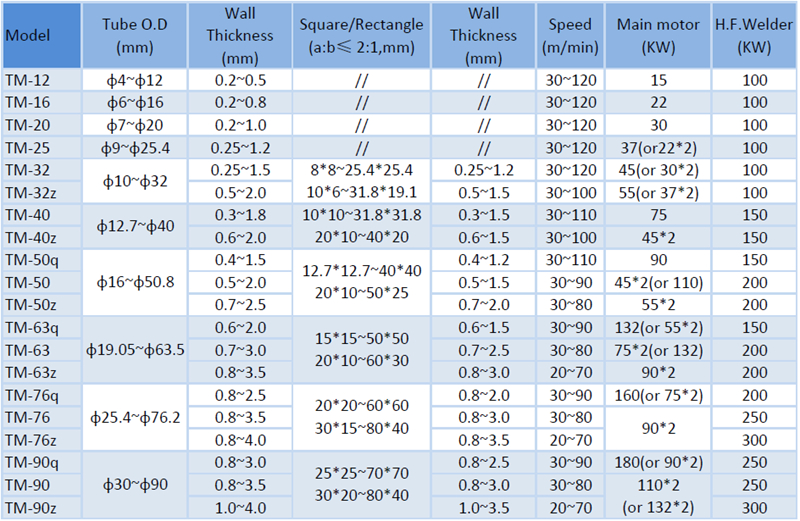

ERW Tube & Pipe Mill Machine Series are the specialized equipment to produce high-frequency straight seam welded pipe and tube for structural pipe and industrial pipe with Φ4.0~Φ273.0mm and the wall thickness δ0.2~12.0 mm.

The whole line can reach high precision and high speed through optimization design, best materials choice, and accurate fabrication and rolls. Within a suitable range of pipe diameter and wall thickness, pipe production speed is adjustable.

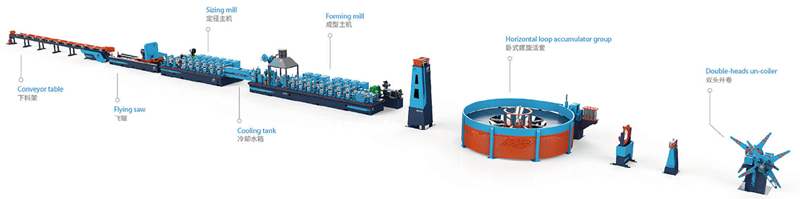

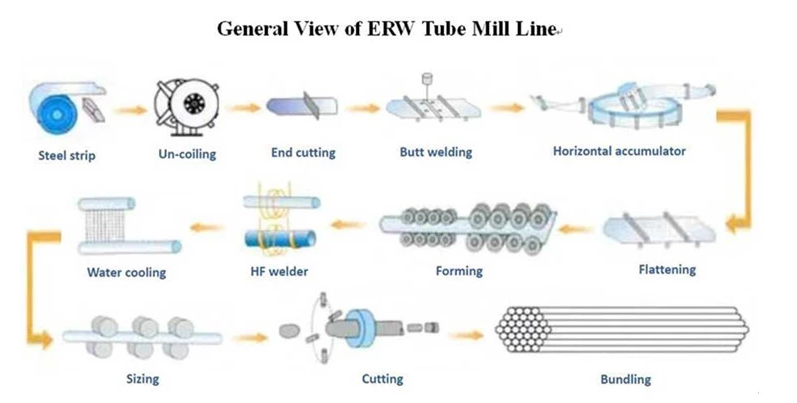

- FLOW CHART

{Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welder station →→ HORIZONTAL SPIRAL ACCUMULATOR →→Forming M/C (Main driving unit① +Flattening Entry unit + Breakdown zone + Fin pass zone + Seam guide unit + High-frequency induction welding system + Squeeze welding roller unit + Outside scarfing unit + Zinc spray patching system for welded seam(optional) + Horizontal ironing stand) + Emulsion water Cooling section + Sizing M/C (Main driving unit② +Sizing zone + Speed testing unit + Turk straightener + Vertical pull-out frame) →→ NC Cold flying saw under computer control→→Run-out table →→{Stacking & packing section(optional)

- Features

1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching.

2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation.

- Application:

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries. -

Newly Arrival Cz Purlin Roll Forming Machine - Metal Deck Roll Forming Machine – COREWIRE

Metal Deck Roll Forming Machine is a color-coated steel plate that is cold-rolled into various wa... -

High Quality for Barbed Wire Fencing Machine - High Speed Barbed Wire Machine – COREWIRE

High Speed Barbed Wire Machine is used to produce barbed wire, which is widely used for playgrou... -

Low MOQ for Inverted Type Take Up Group - Electrode Rods Production Line – COREWIRE

Electrical welding rod production line series has advanced production technology, product quality... -

PriceList for Tube Mill Welding Machine - Automatic High Speed Slitting Line – COREWIRE

Introduction of product operation steps Charging – uncoiler – pinch pre-leveling... -

2021 High quality Purlin Forming Machine - C/Z Purlin Roll Forming Machine – COREWIRE

C/Z-shaped steel is automatically formed by a C-shaped steel forming machine. The c-beam forming... -

Factory directly Saw Blade Grinder Machine – High Speed Nail Making Machine – COREWIRE

This High Speed Nail Making Machine adopts plunger type structure so as to ensure the features su...