Factory Outlets Floor Deck Roll Forming Machine - Guard Rail Roll Forming Machine – COREWIRE Detail:

Guard rail roll forming machine is used to produce guard rails or crash barriers. Hot rolled, galvanized or other steel sheet and coil is suitable roll forming materials for this machine. This machine is mainly made up of loading coil car, exit looping kit, roll former with tooling, automatic stacking device, flying cut-off machine, servo roll feeder, leveler, loading coil car, etc. The finished products are widely used on highway, expressway and other public places to prevent different kinds of accidents and improve safety. They can also be used as fence for livestock farms and other places.

Features

1. This production line can be automatically run by inputting some data (like products length and batches) to the PLC control system.

2. Very strong base frame is configured to avoid vibration.

3. All the rollers have been processed by CNC lathe and polished on the surface to guarantee the accuracy.

4. The rollers have gone through hardened treatment to guarantee long lifespan.

5. We can also design the crash barrier roll forming machine according to customer’s requirement.

Forming Processing

Hydraulic decoiler – Leveling – Feeding – Punching – Conveyor – Roll forming – Auto Stacker

Introduction

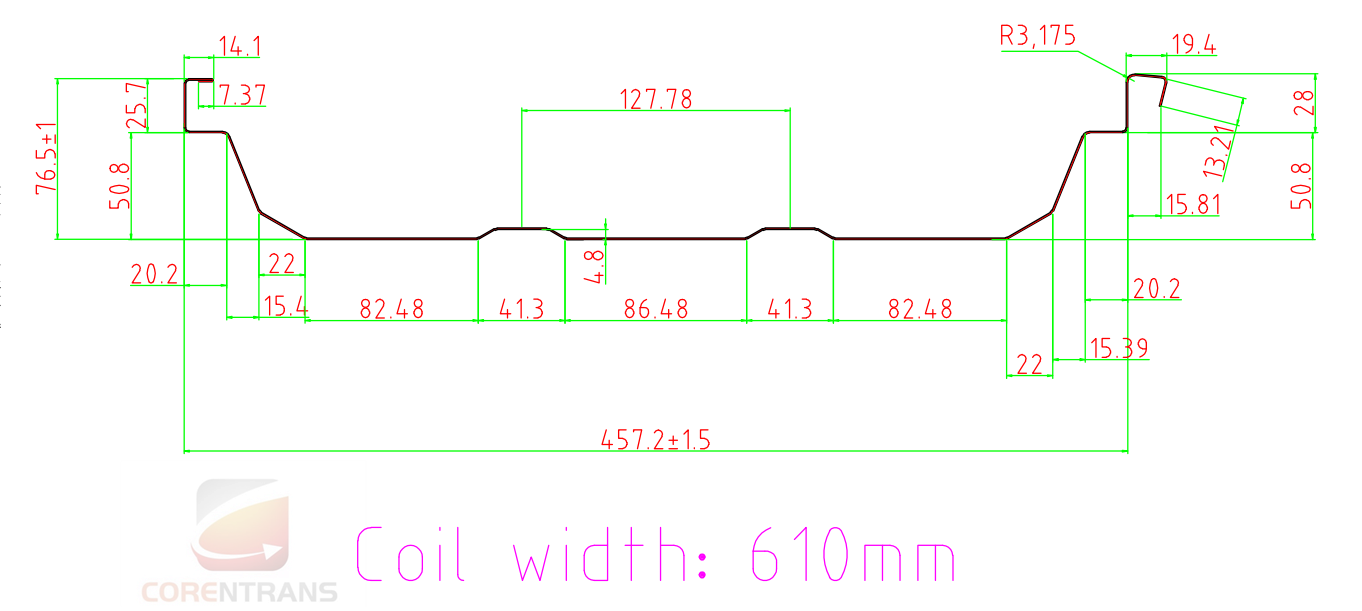

Profile drawing:

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

Product parameters

|

No |

Item | Description |

|

1 |

Machine structure | Wire-electrode cutting frame |

|

2 |

Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

|

3 |

Roller stations | About 12 stations |

|

4 |

Productivity | 0-20m/min |

|

5 |

Drive system | By chain |

|

6 |

Diameter of shaft | ¢70mm solid shaft |

|

7 |

Voltage | 415V 50Hz 3phases (Customized) |

Related products

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Factory Outlets Floor Deck Roll Forming Machine - Guard Rail Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Nigeria, Ghana, Singapore, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

-

Bottom price Chain Link Making Machine - High ...

-

Big Discount Cnc Saw Blade Grinding Machine - ...

-

Manufacturer of Highway Guardrail Roll Roofing ...

-

China Supplier Steel Door Frame Roll Forming Ma...

-

OEM Manufacturer High Quality Steel Tube - Aut...

-

Wholesale Price China Welding Electrodes Produc...