China Manufacturer for Shutter Door Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

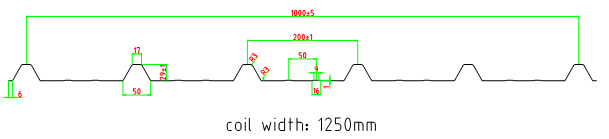

Profile drawing:

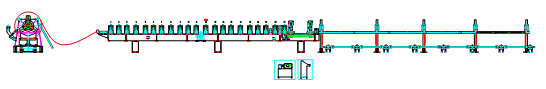

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for China Manufacturer for Shutter Door Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: San Francisco, Maldives, Mexico, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

-

Manufactur standard High Speed Nail Making Mach...

-

Newly Arrival Wet Wire Drawing Machine - Elect...

-

Factory wholesale Erw Mill - Cut to length lin...

-

Wholesale Price China U Purlin - High Speed Ro...

-

Best quality Electrode Rods Oven - High Qualit...

-

Bottom price Roof Sheet Roll Forming Machine -...