China Gold Supplier for Steel Rope Plating Production Line - Cold Rolled Ribbing Machine – COREWIRE Detail:

Product introduction:

|

Product |

Pictures |

Quantity (Set) |

Remark |

| Flying shear cutting machine |

1 |

17KWCNC servo flying shear motor, synchronous motor | |

| Hydraulic Spooler Take-up |

1 |

||

| Control Cabinet |

1 |

Digital control | |

| Straightening Machine |

1 |

Multi-wheel straightening machine to straighten finished products.Multi-wheel small diameter and high frequency straightening method to straighten the finished product.Number of straightening wheels: 24 | |

| Rack |

1 |

||

| Pneumatic Packing Machine |

1 |

Packing Strip width: 14/16mmStrip thickness: 0.38-0.8mmWeight: 5KGPneumatic pressure: 0.42-0.6MpaTension speed: 0.5m/min | |

| Butt Welding machine |

1 |

Motor power: 10KWFunction: Connecting steel bars together |

Product advantages:

1. Cold Rolled Ribbing Machine is the most developed machine with compact structure, small footprint.

2. Cold Rolled Ribbing Machine is featured by small size, short-distance recycling winding and high capacity.

3. Gearbox Reducer of cold rolling ribbed steel bar is large torque, low noise, durable.

4. Advanced frequency inverter technology can save 40-60% power.

5. Pure steel mill foundry and no cracking.

Product Applications:

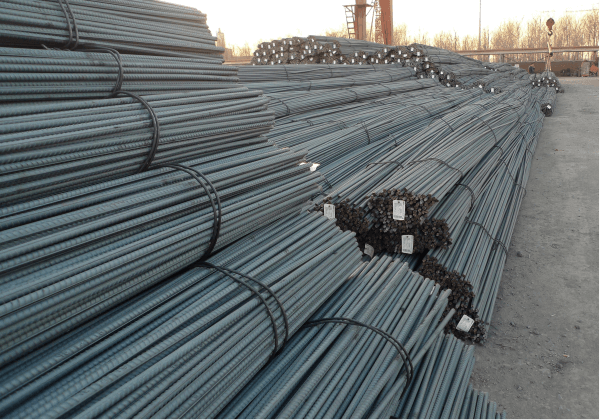

Cold rolled ribbed steel bars have been widely used in construction projects, highways, airports, municipalities, water and electricity pipelines. The high strength of steel can save construction steel and reduce the cost of construction.

Product Parameters

| Item | 20000T | 30000T | 50000T |

| Maximum steel bar process diameter | φ6 -13.5 mm | φ6.5 -12 mm | φ6 -16 mm |

| Diameter of finished steel bar | φ5 -12 mm | φ5.5 -11 mm | Φ6 -14mm |

| Straightening speed | 120 m/min | 180 m/min | 190 m/min |

| Shearing mode | Frequency conversion flying shear | Servo flying shear | Servo flying shear |

| Main motor power | 55-75 KW | 110 KW | 130-160 KW |

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for China Gold Supplier for Steel Rope Plating Production Line - Cold Rolled Ribbing Machine – COREWIRE, The product will supply to all over the world, such as: Swiss, South Africa, USA, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

-

Factory wholesale Electrode Rods Furnace - Hig...

-

Hot-selling Erw Tube Mill Manufacturers - stai...

-

Hot Selling for Slitting Production Line - Hig...

-

Online Exporter Steel Roll Forming Machine - T...

-

High Performance Steel Sheet Embossing Machine ...

-

Discount wholesale Tube Mill Scarfing Tools - ...